DESIGN | BUILD | INSTALL | MODIFY | REPAIR

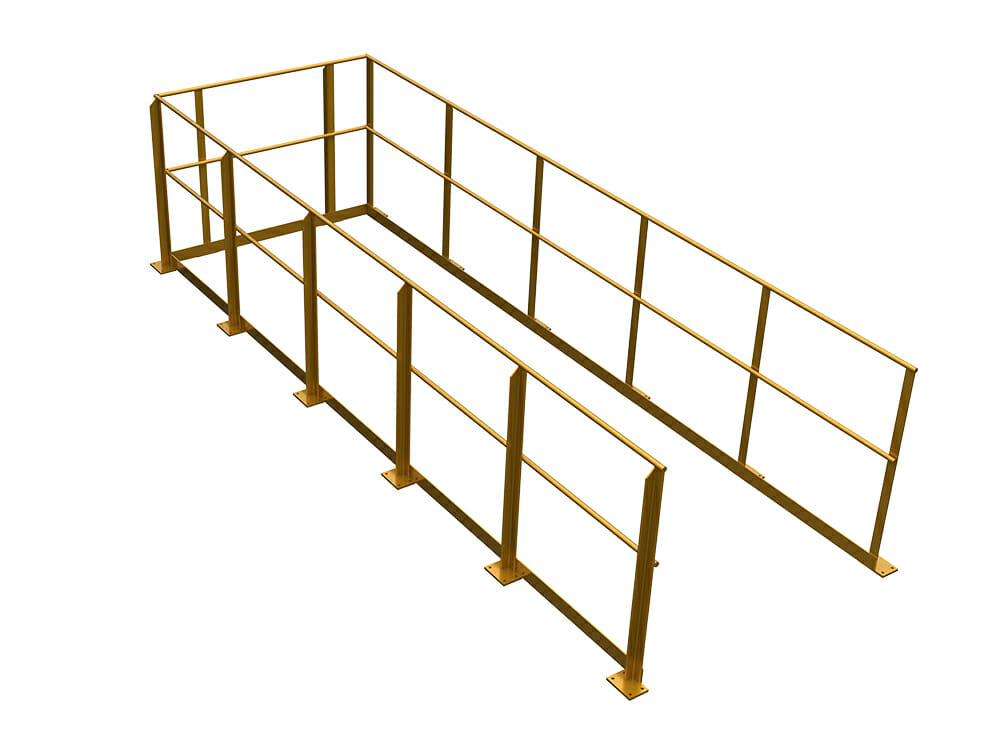

custom

fabrication

services

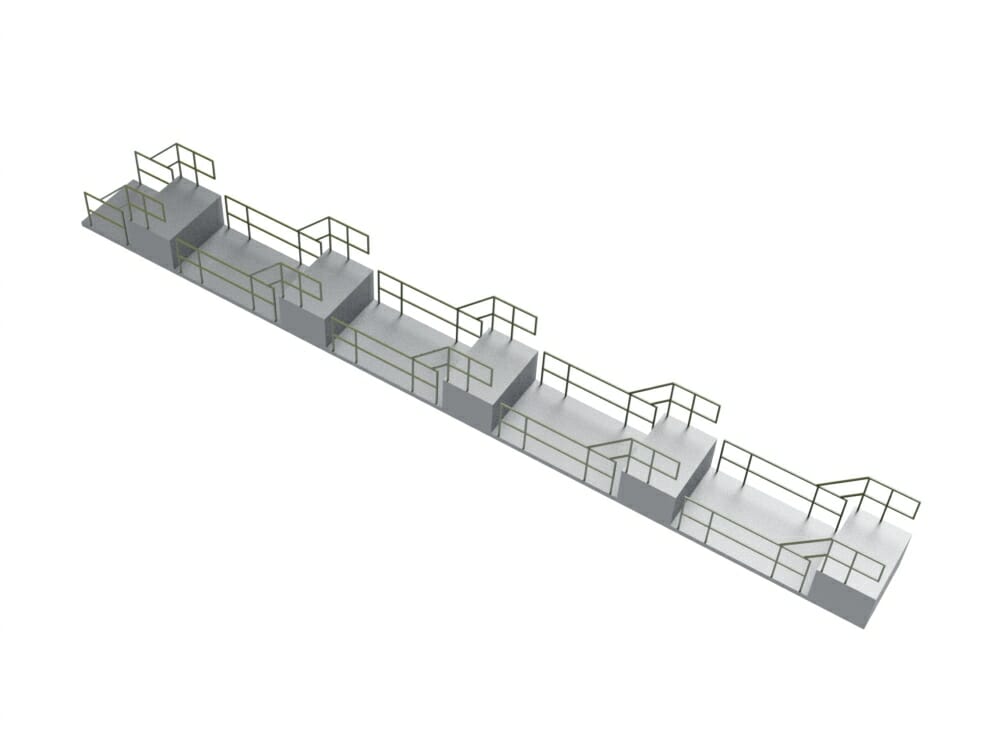

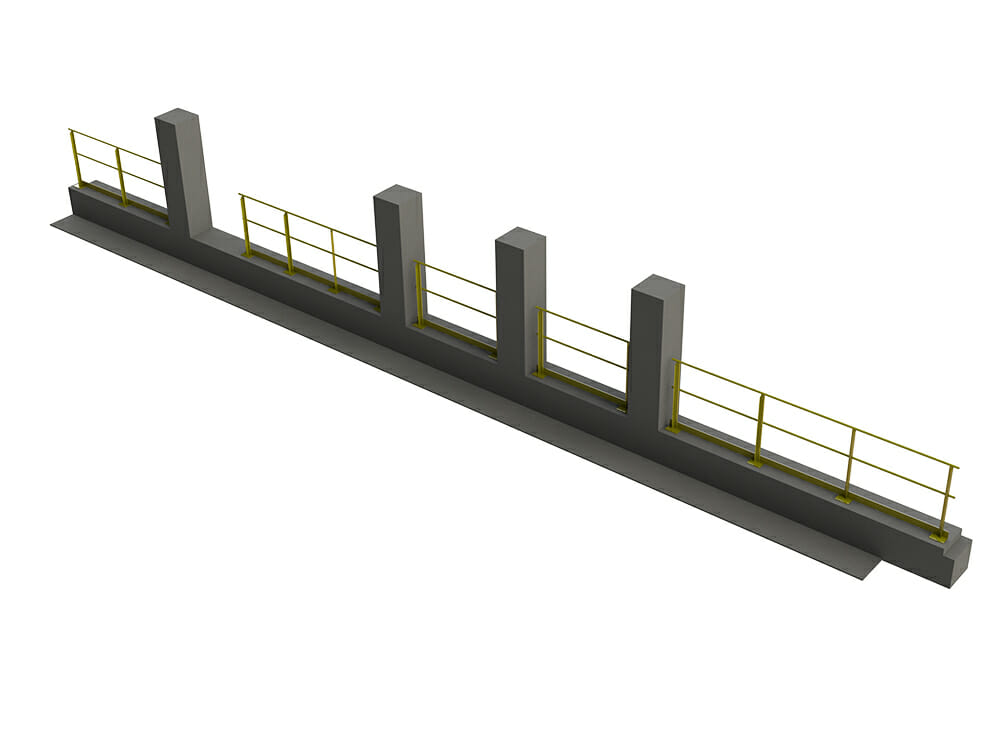

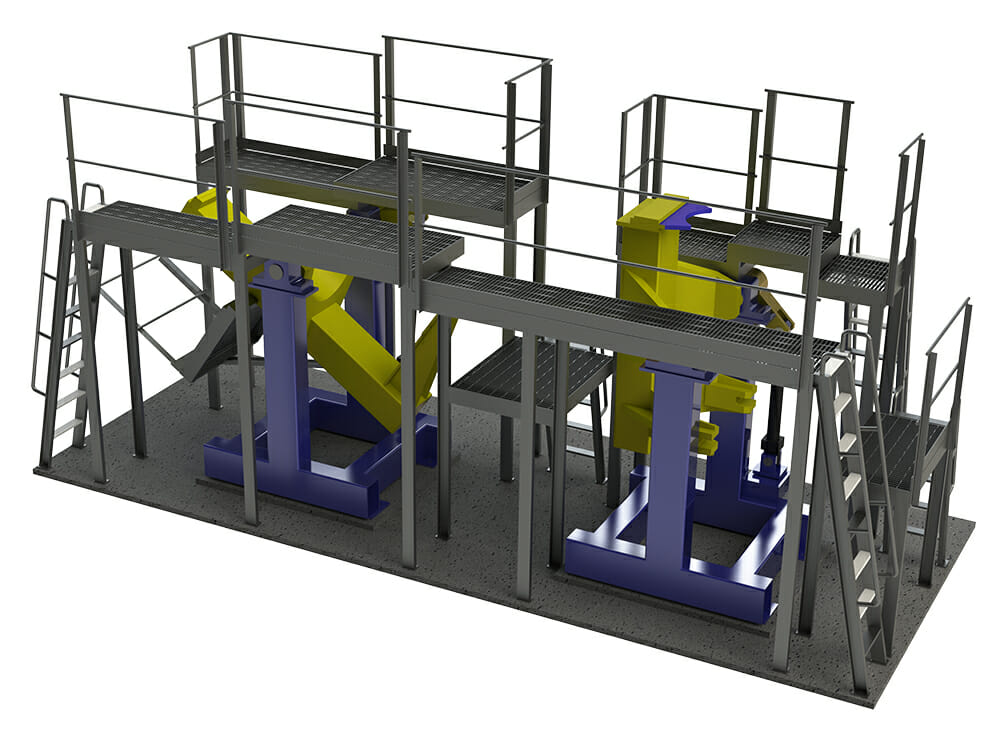

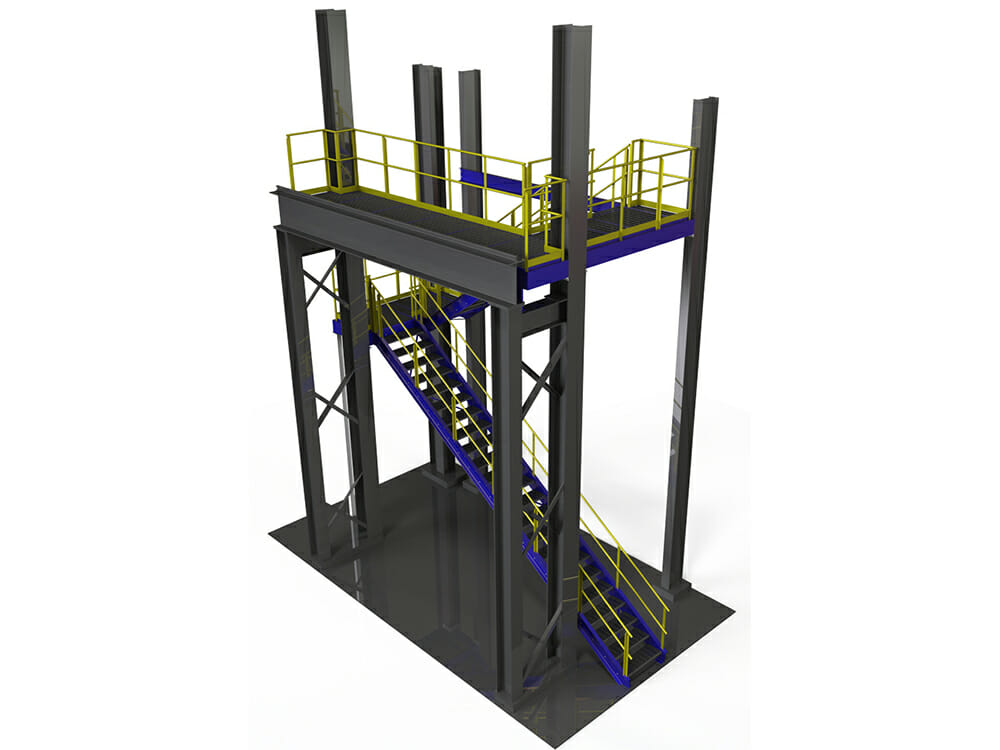

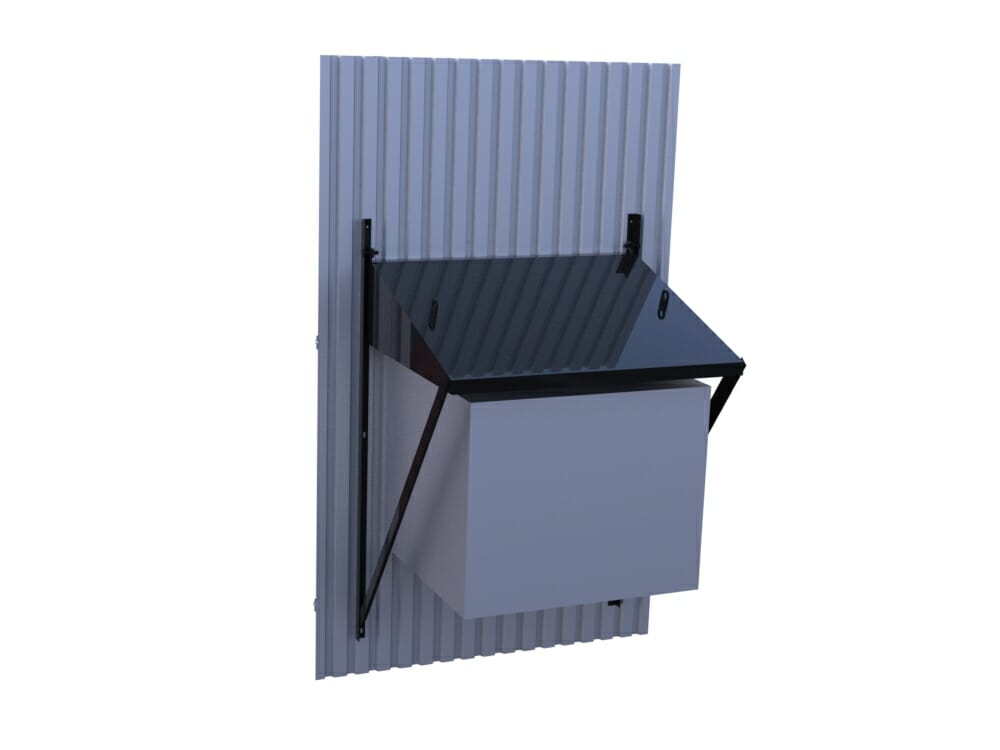

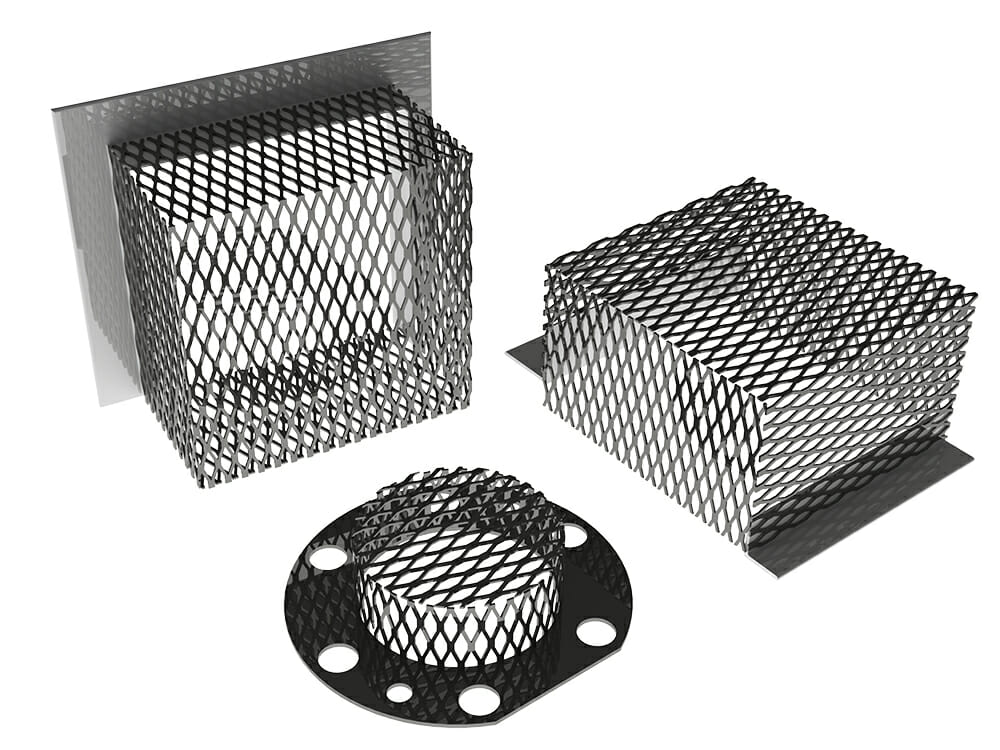

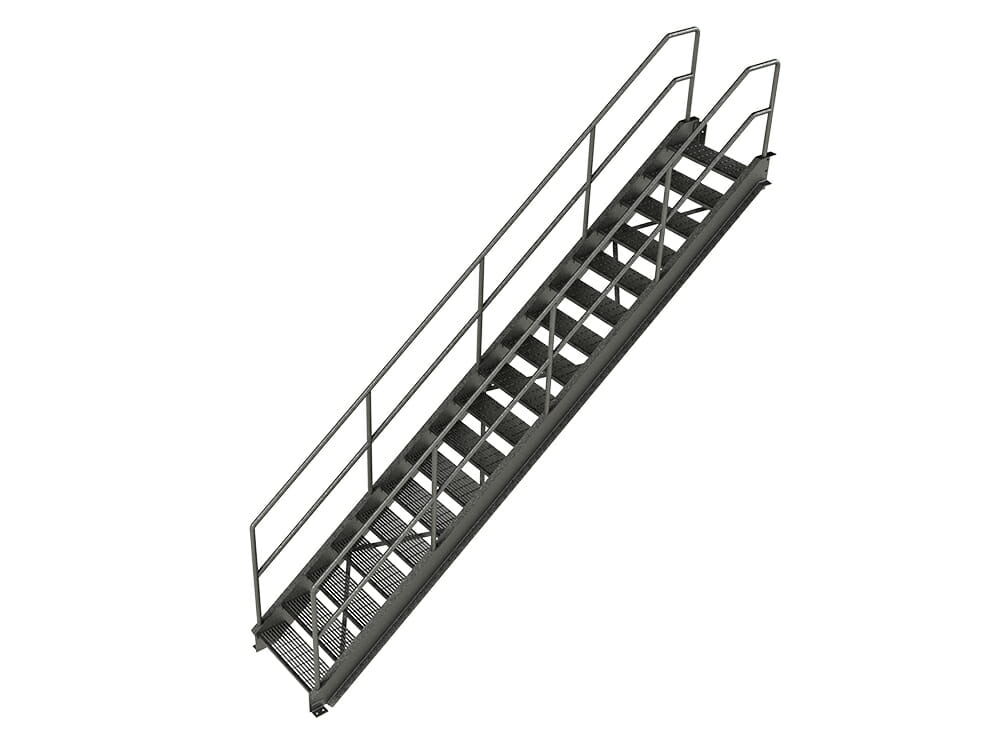

Cascade Fabrication services individuals, companies, and industries with custom metal fabrication. Be it a repair, modification, or a fresh build. We can work with supplied designs or designs for you.

Fabrication can take place within our shop, or on site within the local tri-county area.

Shop Equipment

We have many tools and equipment to assist in our fabrication work:

- 1/4” x 10’ Shear

- 175 Ton AccuPress Brake w/ ETS 3000 Controls

- 18” x 31” Vertical Saw

- 5 Ton Overhead Crane

- 5’ x 10’ Plasma Table (1 1/2” Cap)

- 55 Ton Ironworker

- 90 Ton Piranha

- Carell Double Pinch Structural Steel Rolls

Mobile Equipment

When working in the field we have vehicles and equipment to help transport and install fabrications.

- Outfitted Welding Truck

- Scissor Lift

- Telehandler

- Forklift

- Long Bed Trailers

- Rigging Equipment

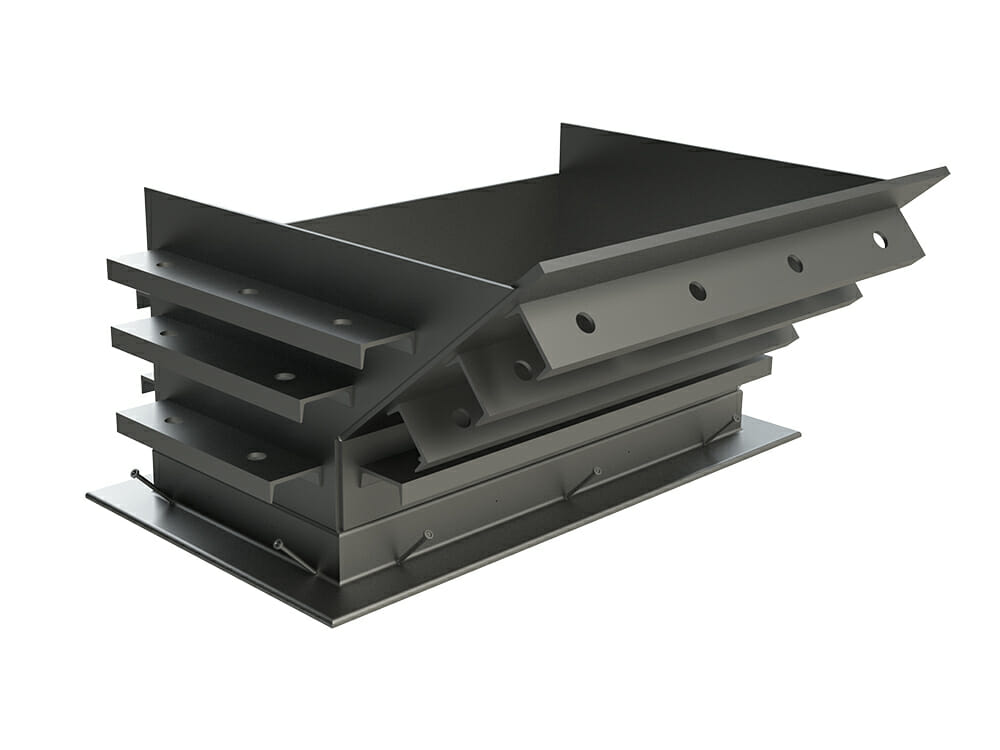

Metals Fabricated

We work with all types, grades, and shapes of metals including but not limited to:

- Carbon Steel

- Stainless Steel

- Aluminum

Sheet

Channel

Angle

Tube/Pipe

Round/Flat Bar

Beam

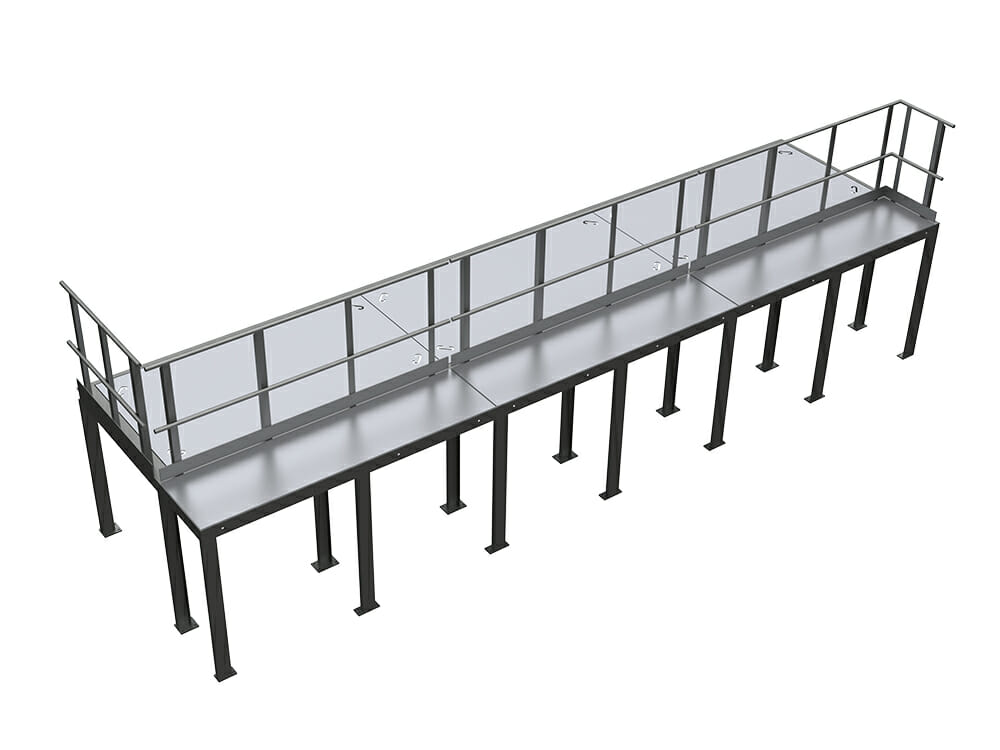

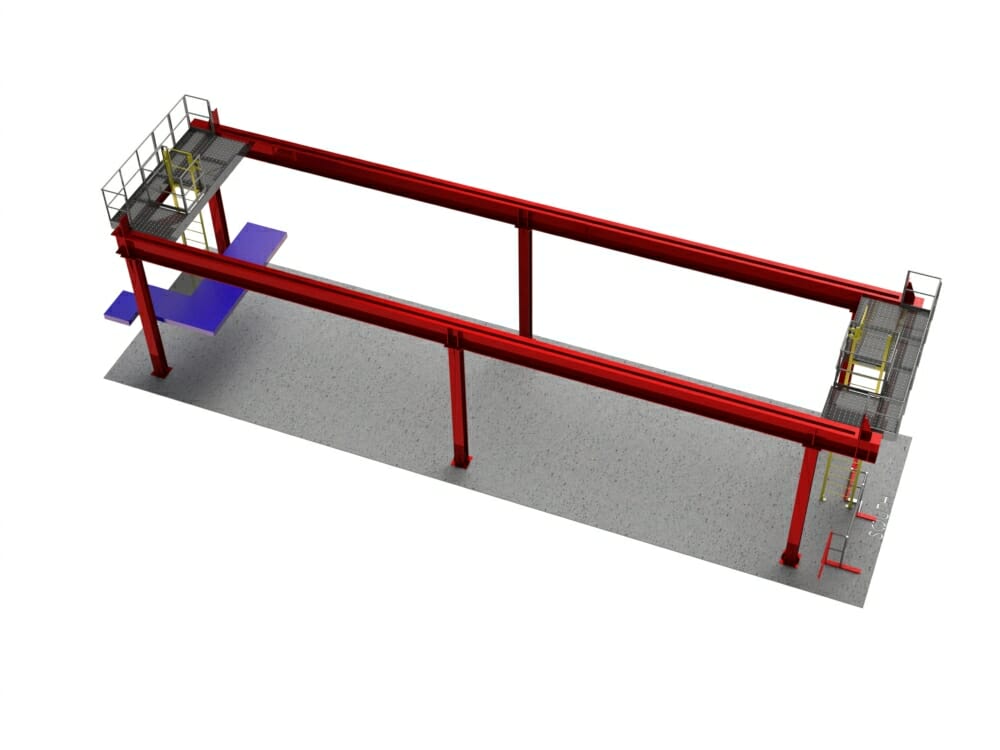

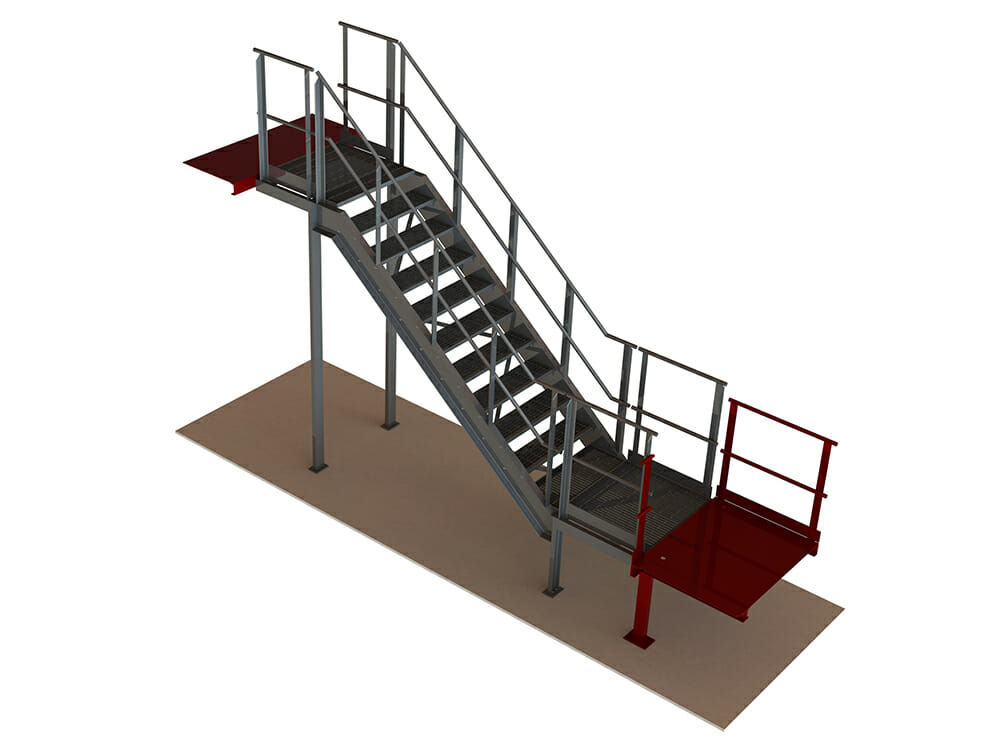

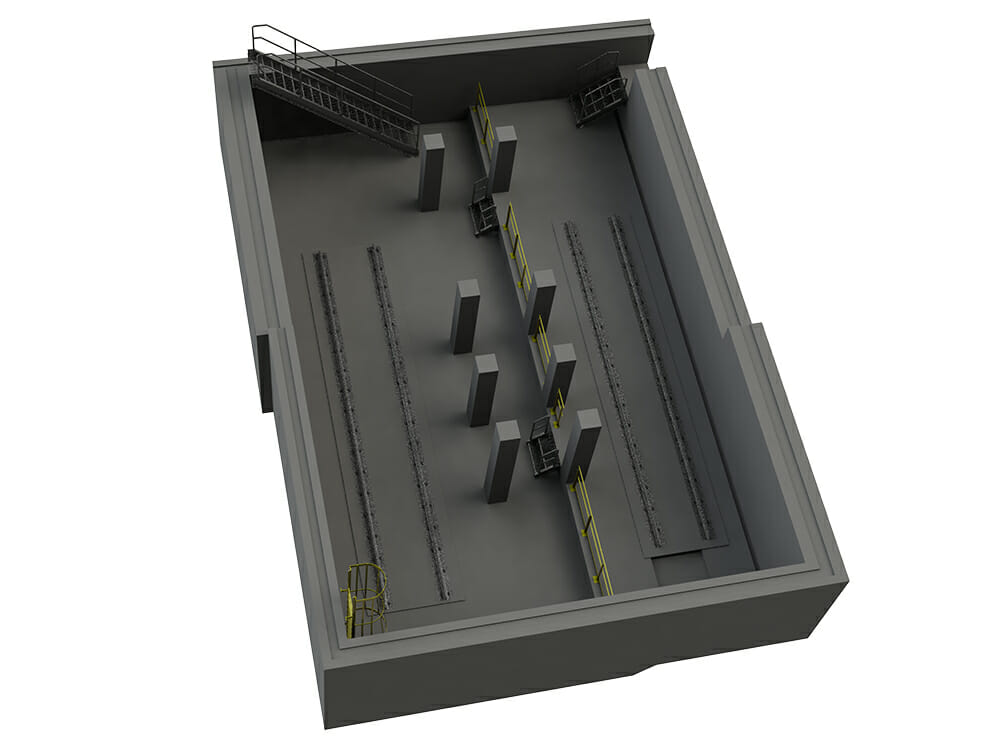

DESIGN CAPABILITIES

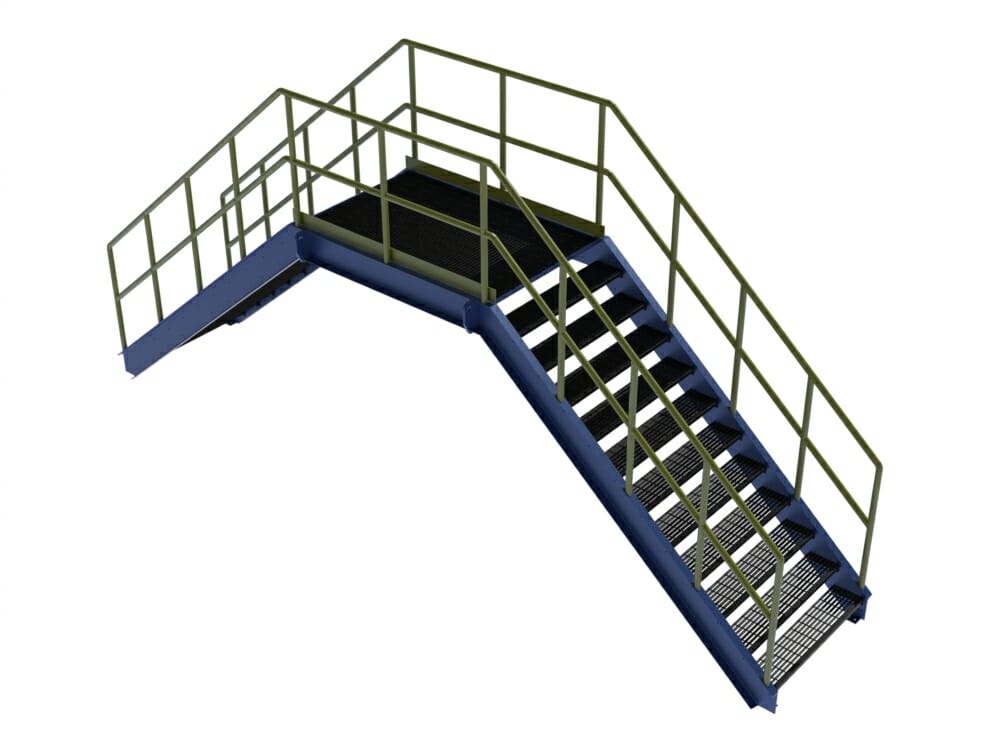

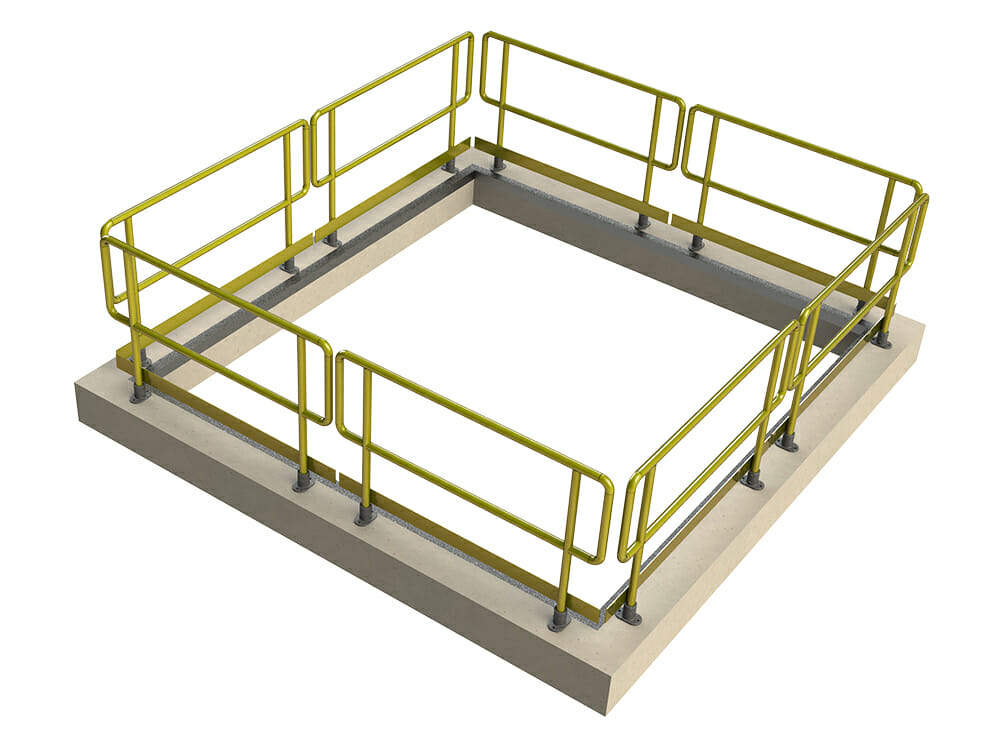

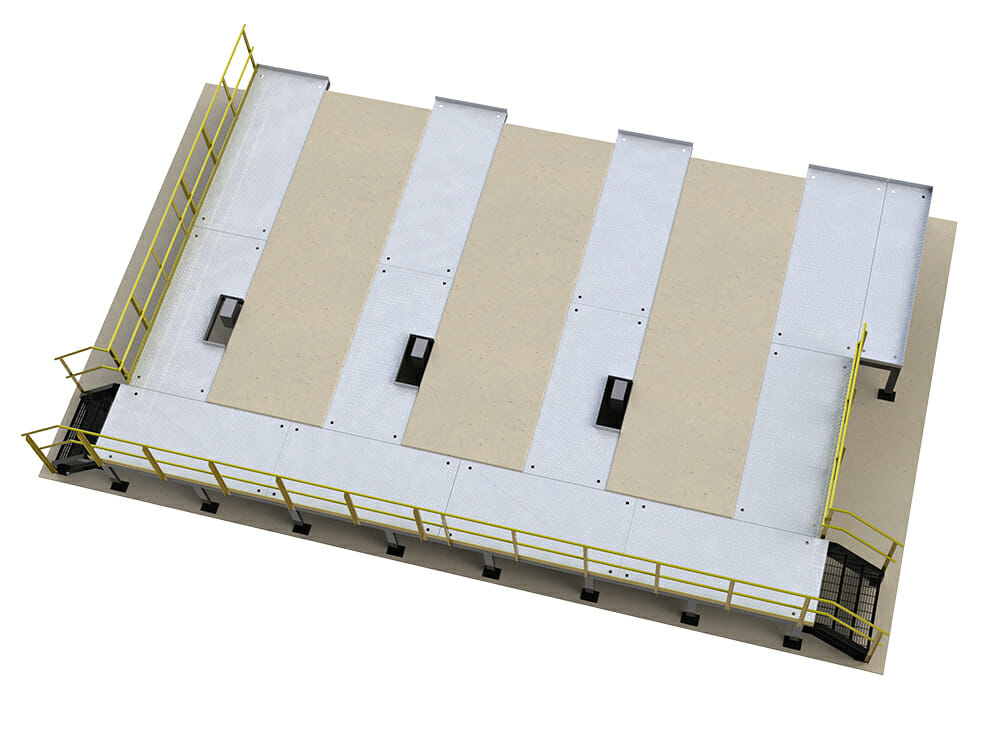

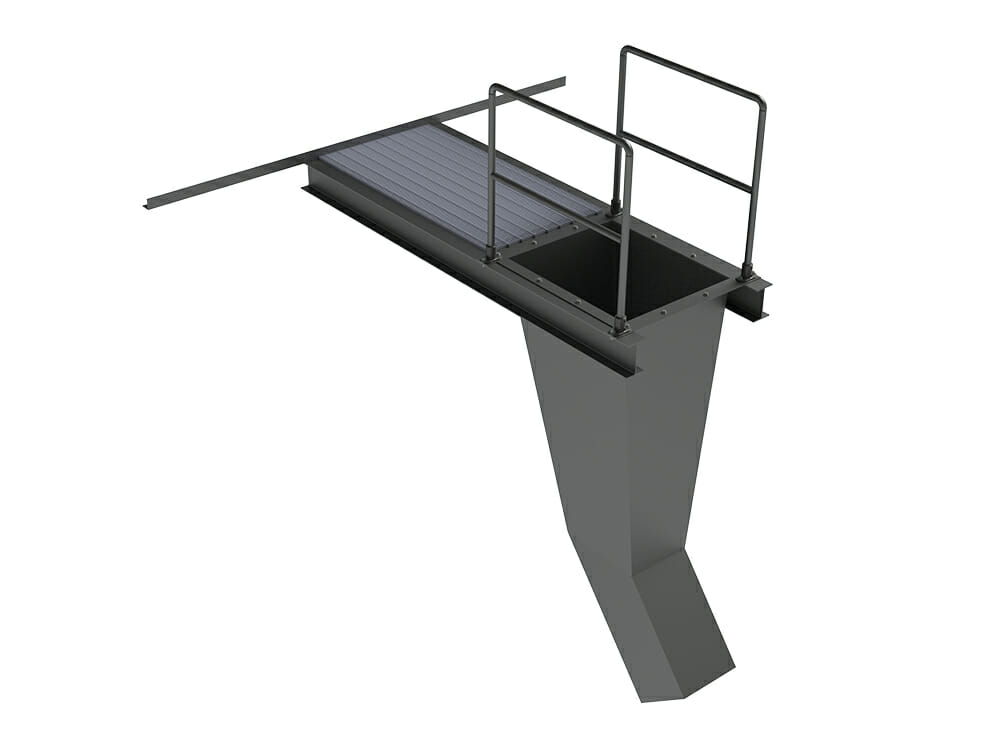

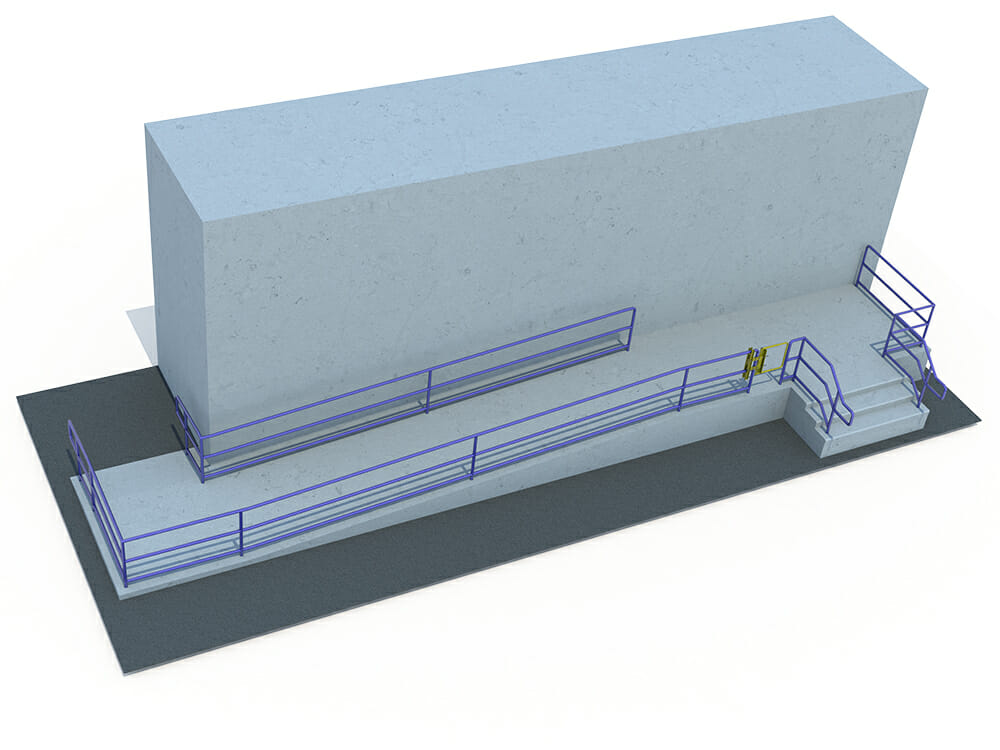

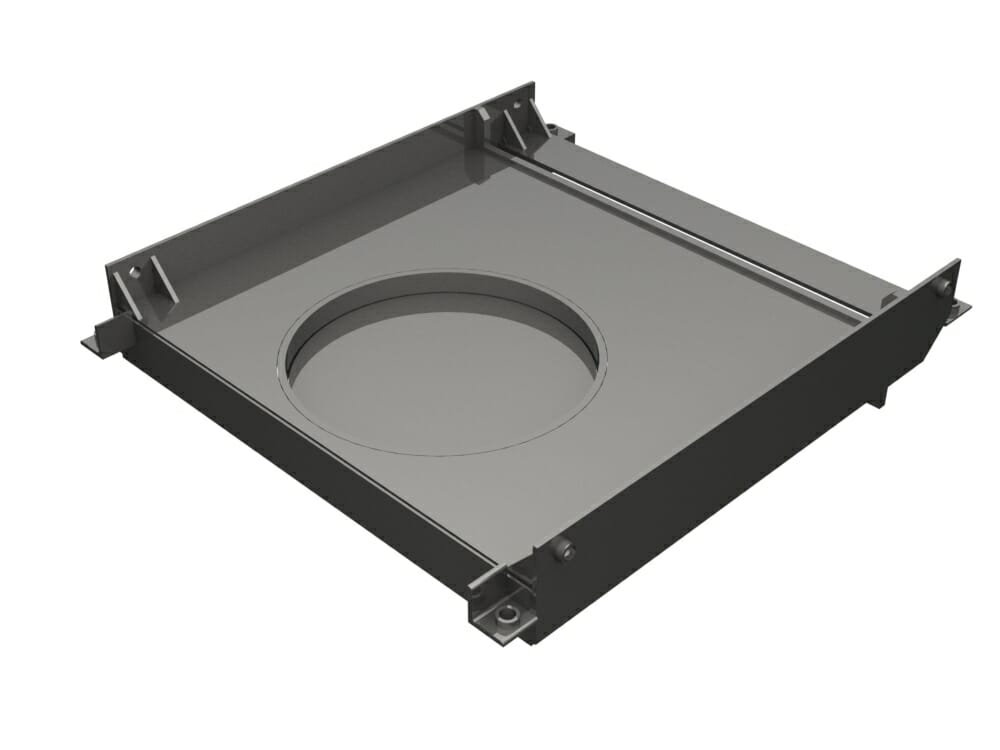

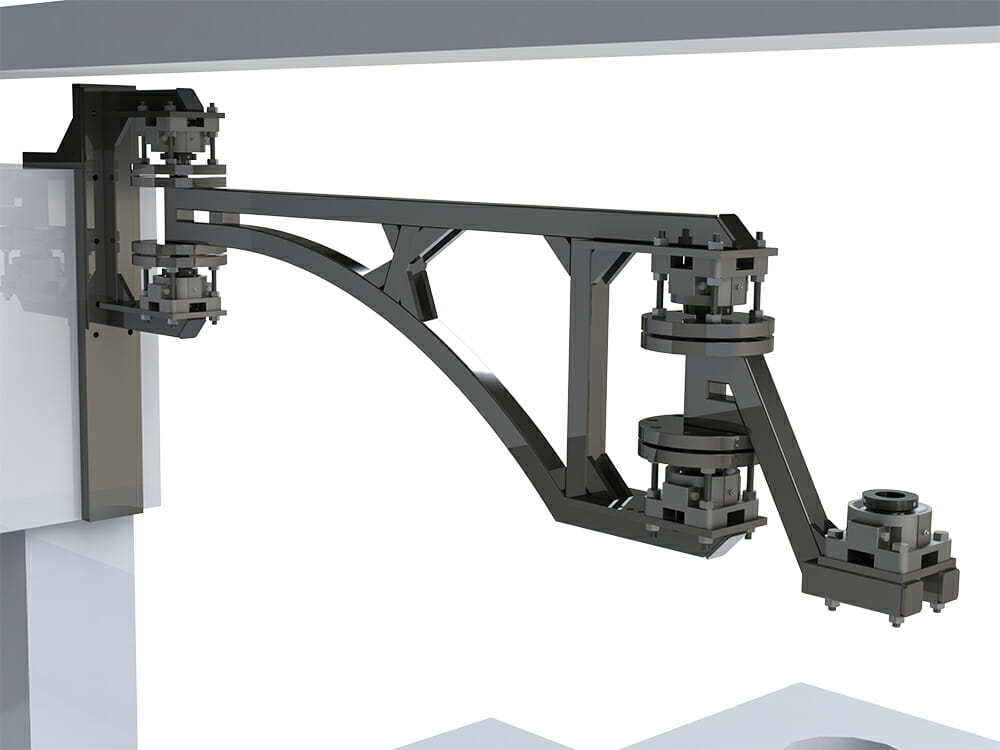

Making use of 3D Parametric Modeling CAD Software (SolidWorks), our experienced drafters ensure quality and accuracy from concept to delivery.

- Accurate model designs and fabrications in 3D.

- Draft 2D drawings for development, verification, approval, and production purposes.

- Verification of supplied designs.

- Simulate real world materials for weights & structural integrity.

- Working relationships with Professional Engineers when needed.

WELDING CAPABILITIES

Many types of welding are performed by our skilled and experienced welders, such as:

- MIG - Gas Metal Arc Welding (GMAW)

- TIG - Gas Tungsten Arc Welding (GTAW)

- Stick - Shielded Metal Arc Welding (SMAW)

- Flux-Cored Arc Welding - (FCAW)